One of the advantages of the CCD method was that it used a simpler rectangular area, rather than overlapping circular cone areas. The scope of the provisions expanded when they appeared in Appendix D of ACI 318-02, which standardized the analysis methodology for post-installed anchors.

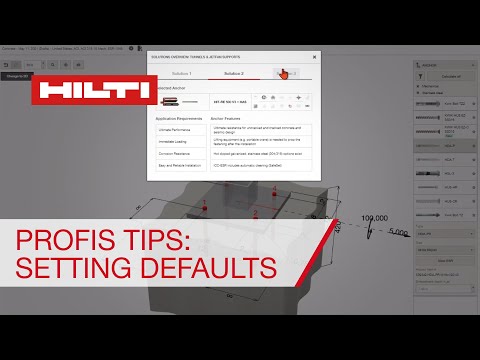

The new provisions also clearly identified specific limit states, which may not have been apparent in older design tables. The CCD method provided better predictions of concrete breakout strengths than the previously common 45-degree cone method. It was initially a strength design option and was limited to cast-in-place anchors only. Evaluate the most suitable and optimized solutions for your build, based on decades of Hilti research and expertise in modular support systems.Concrete Capacity Design (CCD) has been a code methodology for anchor design since it was introduced directly into section 1913 of the 2000 International Building Code (IBC).Have confidence that Hilti PROFIS Installation is integrated into our Hilti products, technologies and engineering backup services – to give you an end-to-end solution from design, construction to building operation.Create sophisticated reports, with detailed structural analysis, showing the displacement, base plate geometry and anchor evaluation of your application – all useful to check your design is safe and ready for inspection.Link seamlessly to Revit® and AutoCAD® so you can export your modular support design directly into your building design software.Link directly to the BIM/CAD Library, full of 2D and 3D objects of Hilti modular support systems – all rigorously tested and code compliant.You can attach your own elements to your design in both design modes. Customize your own design in a 3D editor from scratch or use our template design module to select a design from a wide range of common applications.With Hilti PROFIS Installation design software, you can:

0 kommentar(er)

0 kommentar(er)